SKYACTIV-X – next-generation petrol engine

Featuring Spark-Controlled Compression Ignition, a never-before-seen combustion method, Mazda’s SKYACTIV-X engine represents the second step in Mazda’s quest to develop a petrol engine with the ideal internal combustion mechanism.

Developing compression ignition for petrol engines has long been a goal of engineers. In the SKYACTIV-X, spark plug ignition is used to control compression ignition, resulting in dramatic improvements across a range of important performance indicators.

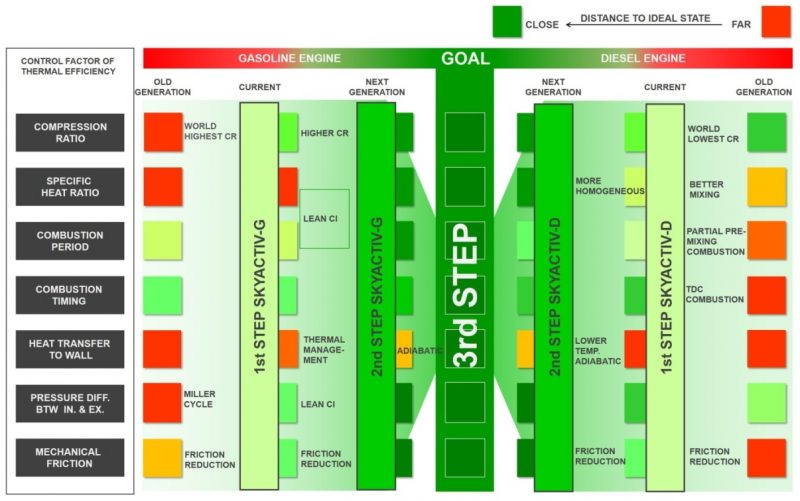

The SKYACTIV-X is a ground-breaking new engine exclusive to Mazda in which the benefits of a spark-ignition petrol engine—expansiveness at high rpms and cleaner exhaust emissions—have been combined with those of a compression-ignition diesel engine—superior initial response and fuel economy—to produce a crossover engine that delivers the best of both worlds. Coming after Mazda’s SKYACTIV-G petrol engine and SKYACTIV-D diesel engine, this third SKYACTIV engine has been given the new name of “X” in recognition of this dual role.

At Mazda, we believe that there is still ample room for further evolution of the internal combustion engine and that this technology has the potential to contribute in a major way to conservation of our global environment. Based on Mazda’s corporate vision of protecting our beautiful planet while enriching people’s lives through the “joy of driving,” we plan to continue on our ceaseless quest to develop the ideal combustion engine.

Aims and concept of the technology

As we have moved along the road map shown above, we have undertaken a fundamental re-examination of the nature of combustion, with the aim of making some major improvements in the efficiency of the internal combustion process.

In the SKYACTIV-G, combustion efficiency is boosted by raising the compression ratio, while cooling losses from the zone of the heat transfer to the chamber wall are reduced through control of cooling water temperatures. Pumping losses and mechanical resistance are reduced through use of the Miller cycle.

In the SKYACTIV-X, the latest SKYACTIV engine, we have worked to boost the air-fuel ratio. In order to do this, we had to enable lean burn, in which larger quantities of air are combusted. The ideal (stoichiometric) air-fuel ratio is 14,7:1. Creating a higher air-to-fuel ratio by more than doubling the amount of air raises the specific heat ratio and lowers the combustion gas temperature. This, in turn, reduces cooling losses. Meanwhile, a design that introduces larger amounts of air reduces the losses from throttle closure, resulting in improved fuel economy.

However, the problem is that if this kind of lean mixture of air and petrol is burned using the flame propagation-based combustion which occurs when a spark plug is used, combustion tends to become unstable. To overcome this problem, compression combustion in high-temperature, high-pressure conditions must be employed. This means that such an engine will need to adopt the compression ignition used by diesel engines. In developing the SKYACTIV-X, we have therefore improved the seven factors which need to be controlled for compression ignition of a lean air-fuel mixture. These include the compression ratio (which needs to be raised in order to realize the required high-temperature, high-pressure conditions), combustion timing near top dead centre (which is found in compression ignition), and a combustion period in which all the fuel burns simultaneously.

Issues associated with homogenous charge compression ignition

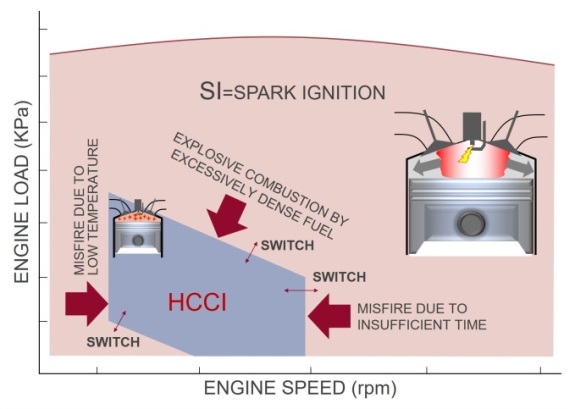

One concept underpinning compression ignition in gasoline engines is homogenous charge compression ignition (HCCI). When a spark plug is used for ignition, the combustion has to spread out from the initial spark, resulting in a slower combustion speed. If, in addition to this, a leaner air-fuel mixture with more air is used, the flames created by the spark plug will fail to spread throughout the combustion chamber. With compression ignition, however, all fuel in the combustion chamber combusts simultaneously, resulting in a far higher combustion speed which, in turn, means that a leaner air-fuel mixture can be burned.

However, HCCI has not yet reached the point where it can be used in commercial applications because it is only used at low revolutions per minute and engine load ranges, and even these ranges are apt to change depending on driving conditions. Furthermore, the very limited range across which HCCI can take place makes it difficult to achieve stable switching between spark ignition and compression ignition.

Until now, overcoming these issues had required a major increase in the compression ratio, a more complex structure and the addition of high-precision controls.

Spark-Controlled Compression Ignition

The breakthrough that has made SKYACTIV-X possible

“Compression ignition doesn’t require a spark plug, but a spark plug will still be needed in the rpm and load ranges where compression ignition cannot take place. Unfortunately, switching between these two modes is extremely difficult.” This is the “received wisdom” about HCCI, setting out the main issue which has prevented HCCI technology from being fully commercialized.

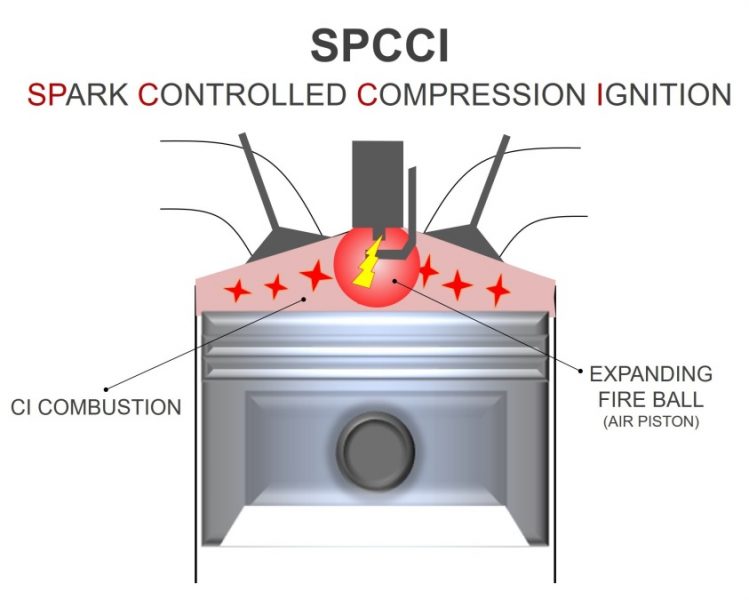

Mazda’s breakthrough has been achieved by questioning the conventional idea that no spark plug is needed for compression ignition and suggesting a different approach instead: “If switching between different combustion modes is difficult, do we really need to switch in the first place?” This concept is the basis of Spark-Controlled Compression Ignition (SPCCI), Mazda’s unique combustion method.

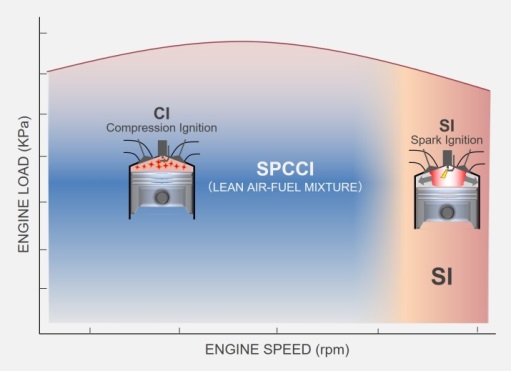

Using SPCCI means that the range where compression ignition can take place (in terms of engine load and rpm) now covers the whole combustion range. That is to say, the potential application of compression ignition has now dramatically expanded, allowing this technology to be used in almost all driving conditions. In other words, because a spark plug is now being used at all times, the engine can switch seamlessly between combustion using compression ignition and combustion using spark ignition.

Key technological features of SPCCI

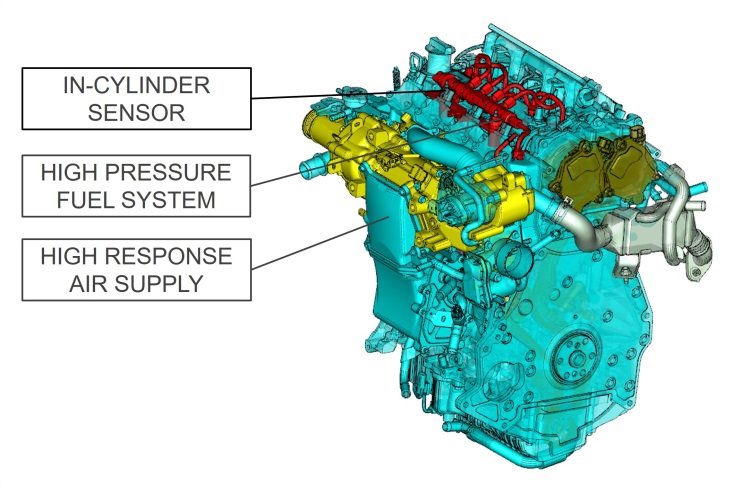

Although SPCCI is an entirely new combustion method, it is based on two existing functions—ignition and injection – which Mazda has further refined and meticulously recombined. To do this, Mazda has further developed several elementary technologies—a new piston head design and super-high-pressure fuel injection system to support compression ignition, and a high-response air supply which can deliver larger amounts of air—and combined these with an in-cylinder sensor which serves to control the entire engine. Compared with the complicated structures that were previously required in order to utilize the HCCI concept, the hardware for SPCCI is simple and lean, with no unnecessary complexity.

Using compression effects created by flame propagation

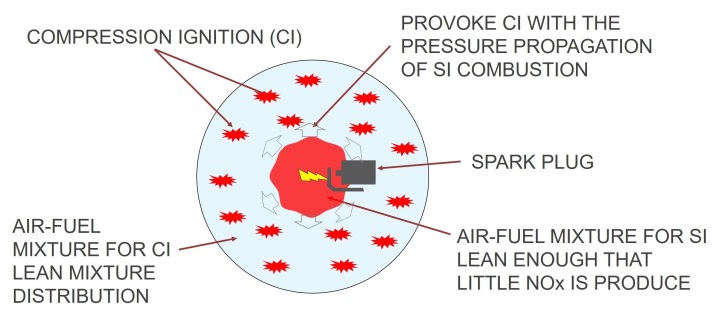

The SPCCI mechanism can be summarized as a system in which the compression effect of spark-ignited localized combustion is used to achieve the required pressure and temperature to bring about compression ignition.

In other words, the geometric compression ratio is raised to the point where the air-fuel mixture is on the verge of igniting (due to compression) at top dead centre. At this point, an expanding fireball created by spark ignition provides the final push that causes the whole mixture to combust. The timing and amount of pressure required are in a continual state of flux depending on constantly-changing driving conditions. The SPCCI system is able to control the spark plug ignition timing, meaning that pressure and temperature within the combustion chamber can be optimized at all times. Because a spark plug is used all the time, the system is able to switch seamlessly to spark ignition combustion in rpm or load ranges where compression ignition would be difficult. In this way, the system ensures that the compression ratio is never raised too high, while enabling a simple design which does not require complicated features such as variable valve timing or a variable compression ratio.

Fuel density distribution within the air-fuel mixture

The SKYACTIV-X controls the distribution of the air-fuel mixture in order to enable lean burn using the SPCCI mechanism. First, a lean air-fuel mixture for compression ignition is distributed throughout the combustion chamber. Next, precision fuel injection and swirl is used to create a zone of richer air-fuel mixture—rich enough to be ignited with a spark and to minimize nitrous oxide production—around the spark plug. Using these techniques, SPCCI ensures stable combustion.

Controlling the air-fuel mixture to prevent abnormal combustion

Split fuel injection

In order to prevent the abnormal combustion which can occur when rich air-fuel mixtures are compressed for long periods of time—a longstanding issue for HCCI—SPCCI adopts a split fuel injection system, in which part of the fuel is injected during the air intake process and part is injected during the compression process. First, the low-density lean mixture for the lean burn is injected during the air intake process; then, during the compression stroke, a separate injection creates the richer air-fuel mixture that is ignited around the spark plug. This not only distributes the density of the air-fuel mixture so as to allow SPCCI to take place but also minimizes the time lag until the air-fuel mixture ignites under compression, effectively controlling abnormal combustion.

Super-high-pressure fuel injection system

To minimize compression time and make compression ignition as efficient as possible, the fuel must be vaporized and atomized very quickly and then immediately dispersed around the whole of the cylinder. The SKYACTIV-X therefore features a system capable of injecting fuel at super-high pressure from a multi-hole fuel injector positioned in the centre of the combustion chamber. This causes the fuel to be vaporized and atomized instantly, while powerful turbulence is simultaneously created, greatly improving ignition stability and combustion speed. Super-high-pressure fuel injection enables SPCCI, which suppresses abnormal combustion even at full throttle/low rpms where traditional gasoline engines have to retard ignition and thus sacrifice efficiency and power.

Adoption of the in-cylinder pressure sensor

In addition to the abovementioned technologies for preventing abnormal combustion, an in-cylinder sensor has also been introduced as a monitoring control; by continually observing whether the above controls are bringing about proper combustion and compensating in real time for any deviations from intended outcomes, it ensures continuously optimized combustion.

Based on the techniques set out above, SPCCI has expanded the zone of compression ignition right into the full throttle range, and enables smooth switching between SPCCI combustion and spark ignition combustion.

This new combustion method does not merely use spark ignition to assist compression ignition, but delivers an all-encompassing combustion control system which includes control of in-cylinder temperature and pressure and control of the fuel injection’s air-fuel mixture distribution density and exhaust gas recirculation (EGR).

Value provided by SKYACTIV-X

Dramatically improved output performance and responsiveness

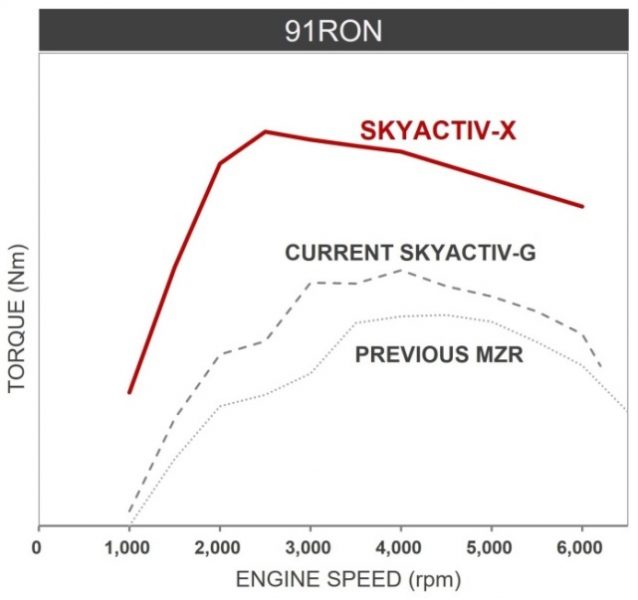

With an engine displacement of 2.0L, the SKYACTIV-X delivers at least 10 percent more torque than the current SKYACTIV-G, and up to 30 percent more at certain rpms (data as of August 2017, during the development process). In addition, because the throttle valve is open most of the time, it exhibits the superior initial acceleration response found in diesel engines which do not have a throttle valve. On the other hand, the SKYACTIV-X spins up into the higher rpm ranges as smoothly and easily as a typical petrol engine.

Target figures for SKYACTIV-X output performance

(*data as of August 2017, during the development process)

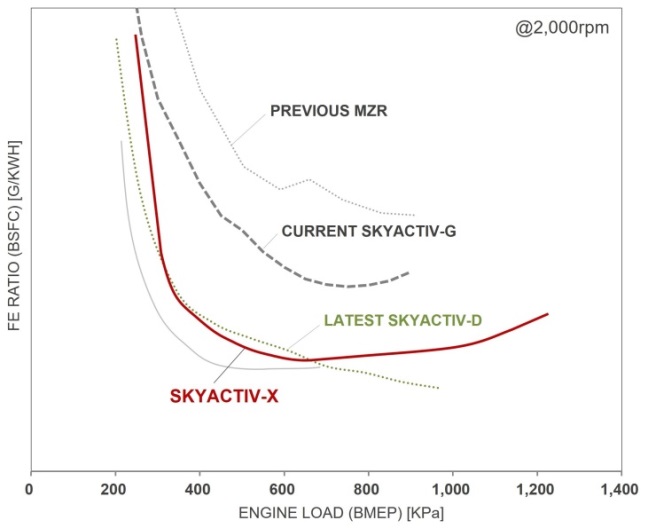

Dramatic improvement in fuel economy

In a vehicle with a 2.0L engine displacement, the SKYACTIV-X delivers a 20 percent improvement in fuel economy compared to the SKYACTIV-G, a dramatic increase. Furthermore, in areas where low vehicle speeds are used frequently, fuel economy can be improved by up to 30 percent thanks to the use of super lean combustion. Compared to the MZR engine of 2008, fuel economy is improved a dramatic 35-40 percent, and SKYACTIV-X even equals or exceeds Mazda’s latest diesel engine, SKYACTIV-D, in fuel efficiency. With improvements being especially great in the light engine load range, this engine challenges the commonly-held belief that a large engine displacement means poor fuel economy.

Target figures for SKYACTIV-X’s fuel economy performance

(*data as of August 2017, during the development process)

The range where the engine is able to deliver excellent fuel economy has been dramatically expanded with the use of the SKYACTIV-X, meaning that this system is able to deliver lower fuel consumption than ever before in a whole range of driving scenarios, including city driving, long-distance driving on expressways and more.

Unique to Mazda, the SKYACTIV-X is a new kind of combustion engine that combines the advantages of gasoline and diesel engines to achieve outstanding environmental performance and uncompromised power and acceleration performance. This revolutionary technology represents the start of an exciting new stage in our quest to develop the ideal internal combustion engine. Fully supporting the Jinba Ittai driving experience Mazda aims to provide, SKYACTIV-X was developed in consideration of our planet and all who live here.